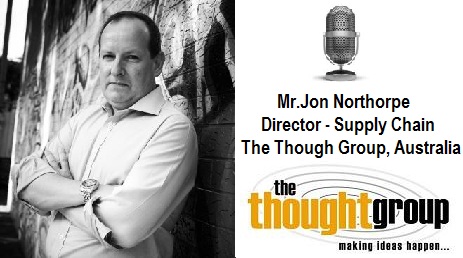

1. Please brief us about your profile at The Thought Group?

The Thought Group is a niche supply chain consulting company based in Melbourne Australia. With extensive experience of operating across both Australasia and Asia we seek to provide a more practical and hands-on approach to supply chain issues ranging from project management and procurement through to interim management.

2. What are the significant milestones achieved under your leadership at The Thought Group?

We have been operating for over five years and have an established base of national and multinational clients. During this time we have provided services for strategic network re-design, the design, development and delivery of several distribution centres and facilities and the improvement of supply chain costs.

3. What are the key challenges that companies face today in their supply chain?

We see that few companies are able to differentiate between cost and value. Typically most companies believe that the establishment of best cost in the components of the supply chain means that ultimately this will deliver best value. In most cases our experience shows that when the factors of best cost combine they rarely deliver best value.

4. There seems to be lot of buzz that cloud computing may replace traditional ERP tools used in supply chain? Do you see any benefits of cloud computing in supply chain?

The key benefits we see in cloud computing is the ability to share more data, more freely, more easily. Typically data collation has been difficult working in multi-site, multi-region environments. The use of cloud based technology for supply chain analysis assists in better data collation that ultimately delivers more accurate results in a timelier manner.

5. Do you use any tools to manage or monitor Supply Chain Risk?

We use traditional supply chain network and forecasting tools but rarely utilise them to manage risk. People are sceptical about the ability of these tools, especially inventory forecasting tools, to manage supply chains regularly manually intervening and over stocking supply channels. Whilst conscious about lead times and inventory levels supply chain risk, in our region, appears to relate predominantly to relationships with end-customers and retailers purely based on DIFOT measurement.

6. SAP acquired Ariba, IBM acquired Emptoris and Oracle acquired Endeca. Do you think this trend of acquiring spend management companies will continue?

ERP companies believe that these type tools will better assist with spend management processes. The key issue however is that they typically, given the “lag” nature of many supply chain functions, only record the spend after it occurs and our view is that if the correct processes are in place within a business these systems become a further step in the process rather than a useful management tool.

7. Do you see any significant changes happening in the near future in supply chain management?

The supply chain industry is a world full of buzz words and technology. RFID, route optimisation, network re-engineering are all currently hip and trendy but ultimately everything comes down to hard-nosed operational logic. In many cases the fundamentals lie with the people inside the business and the knowledge they retain. Companies often choose to run supply chain re-engineering processes that disengage these people in favour of technology. Our experience has shown that, without relevance to the knowledge that many of these people hold inside a business, the tools used in the processes rarely deliver a viable outcome and become expensive toys. We believe more human interactive tools will need to be the way of the future to better assist in planning and maintaining the supply chain.

8. There was a lot of hype and buzz about the usage of RFID in tracking consignments but it really never took off since scalability was a problem and not many companies could afford it. Do you see that changing?

How much data can an individual/business collate and use? RFID technology generates significant volumes of data much of which is worthless. RFID, in specific applications, performing specific tasks, is of value however there is a need to decipher the real need versus the supposed want for the application of the technology.

9. Do you use services of any of the firms listed below to analyze your spend or optimize your supply chain?

- Zycus (www.zycus.com)

- Ariba (www.ariba.com)

- Endeca (www.endeca.com)

- Emptoris (www.emptoris.com)

- Global eProcure (www.gep.com)

We are a small consultancy that typically sees these tools used by large corporations to manage spending through PO Management systems. Our limited exposure to several of these systems has not been good

10. Currently Green Supply Chain Management and Carbon credits seem to be hot topics within Supply Chain. What are your thoughts?

We have seen and heard of green initiatives in the supply chain for the last 15 years. Our view is that, until recently, these were buzz words that, when push came to shove in negotiation, were discarded in favour of lower cost. The introduction of a carbon tax here in Australia has changed thinking, potentially only temporarily, but ultimately a customer’s propensity for green comes down to cost, nothing else…

11. In today’s scenario, Companies scramble to achieve cost savings in procurement and use market research to help in their decision making process. Have you used any of these companies that are known to offer procurement intelligence services?

- Smart cube (www.thesmartcube.com)

- Denali Intelligence (www.denaliintelligence.com)

- Infiniti Research (www.infiniti-research.com)

- Global eProcure (www.gep.com)

We have not worked with any of the above companies nor seen much evidence of them in the Australian market.

12. Today it’s all about saving costs in procurement. Companies are aggressive in achieving cost savings. Due to this supplier’s profitability has dropped. Do you think this sets a bad precedent for new suppliers to enter the market?

Many companies appear to believe that “squeezing” lower cost from a supplier delivers better value. Our approach and experience suggests that most companies need to work smarter, not harder and this will drive more value than just pure cost reduction exercises.

13. Strategic Sourcing plays a key role in helping companies achieve costs savings. At the same time companies are staggering for want of new strategies. This is because they are unable to find new strategies every year and run out of ideas. So is savings possible every year?

Our broad experience has shown us that the use of smart, practical thorough processes in day-to-day operations will deliver better value than most strategic sourcing programs. Sourcing typically relies on examining historic data and measuring it against actual and future cost, this strategy seems to be just reducing historic costs opposed to developing a better understanding of the value that can be created by looking more inwardly.

14. Reverse Auctioning is extensively used to procure products at the best cost. What are some of the other ways to reduce procurement costs?

Again, our experience is companies need to work smarter and not harder. Better planning and analysis of the actual costs incurred rather than the costs associated with what people believe they have spent appears to deliver better benefits in the supply chain arena.

15. With global demand rising for supply chain professionals and a shortage of trained manpower, how do you think this situation can be rectified?

Employment, at all levels of the industry is a major challenge facing almost every employer and sector. The supply chain, like most industries has a sexy and not so sexy side. In the not so appealing areas of the industry companies have typically, at an operational level, been able to develop people from “off the floor” and train them in all aspects of the supply chain. With these more functional areas of the industry becoming seen as less attractive places to work, the opportunity to “harvest” these staff has become harder and the need to import talent from other areas has become an even harder challenge. At the other end of the scale, the ability to attract analysts and graduates is seemingly relatively easy, that is until they become exposed to a business environment that typically operates seven days a week, 24 hours a day.

The critical issues for the industry therefore are creating an environment that offers stability and longevity for all levels of employee. The introduction of handling systems and operational tools is critical to this development however the maintenance of practical skills, especially in transportation and warehousing is just as critical to the development of a broader skills base.

Either way, there is no quick fix. Employers must, to optimise their supply chains, invest heavily in their people in order to create a level of depth and retention.