EPDM (Ethylene Propylene Diene Monomer) is an elastomer. It denotes a terpolymer based on three monomers namely ethylene, propylene and a non-conjugated diene. EPDM finds use as elastomer in several growth oriented application sectors such as automobile, building and construction, wires and cables, etc.

Supply scenario -Period 2011

Global installed capacity: 1,266,000 metric tonnes

Capacity utilization: 90% on an average

Global production: Around 1,394,000 metric tonnes

Future installed capacity and production estimates (In metric tonnes)

|

Period

|

**Installed capacity

|

*Production

|

|

2011

|

1,266,000

|

1,139,400

|

|

2015

|

1,401,000

|

1,260,900

|

|

2020

|

1,521,000

|

1,368,900

|

*Considering capacity utilization of 90%

**Considering all the announced projects would be commissioned by 2016

Demand drivers and growth

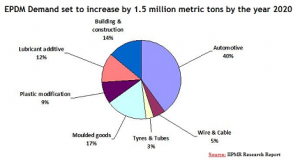

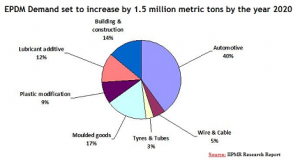

EPDM is the most used non-tyre synthetic rubber and is recording steady demand growth amongst the synthetic rubbers. The growth in demand for EPDM will be driven by the performance of the application sectors, of which automobile sector constitutes the largest segment. The application sectors are growth oriented.

Overall AAGR through 2020 – 4.6%

Global demand for EPDM – Period 2011

Global demand – .14 million tonnes per annum

Pattern of application sectorwise demand

Projected demand supply scenario – Period 2020 (in million metric tonnes per annum)

|

Period

|

**Installed capacity

|

*Production

|

Demand

|

Gap in supply

|

|

2011

|

1.266

|

1.14

|

1.14

|

Matches the demand

|

|

2015

|

1.401

|

1.26

|

1.37

|

0.11

|

|

2020

|

1.521

|

1.37

|

1.72

|

0.35

|

Demand supply scenario

Globally, EPDM is likely to be in tight supply situation, in view of its steady growth in demand and new capacity creation not catching up with the growth in the demand. In Asia Pacific region, particularly in countries like India and China, the demand growth is likely to be high in the region of 8.5% per annum. Automotive industry drives the demand for EPDM, followed by wiring and cable insulation, moulded products and rubber hoses for industry. Such user industries have high level of relevance to the industrial and economic growth pattern in all regions. Considering the likely growth in demand in diversified application sectors in all regions, there is strong case for capacity creation for EPDM.

Recommendation

- Technology for the EPDM project has to be sourced from well established producer

- It is necessary to have firm tie up arrangement for the long term supply of feed stock, namely ethylene and propylene.

- It is preferable to locate the project close to the ethylene cracker.

- The global market can be targeted for the product outlet

- Raw material availability has to be tied up with the supplier on long term contract.

For more details about Supply Chain Course and Market Research Training, please visit http://www.iipmr.com

Global Demand for EPDM (Ethylene Propylene Diene Monomer) is set to increase by 1.5 Million Tons by 2020

2 votes, 5.00 avg. rating (97% score)